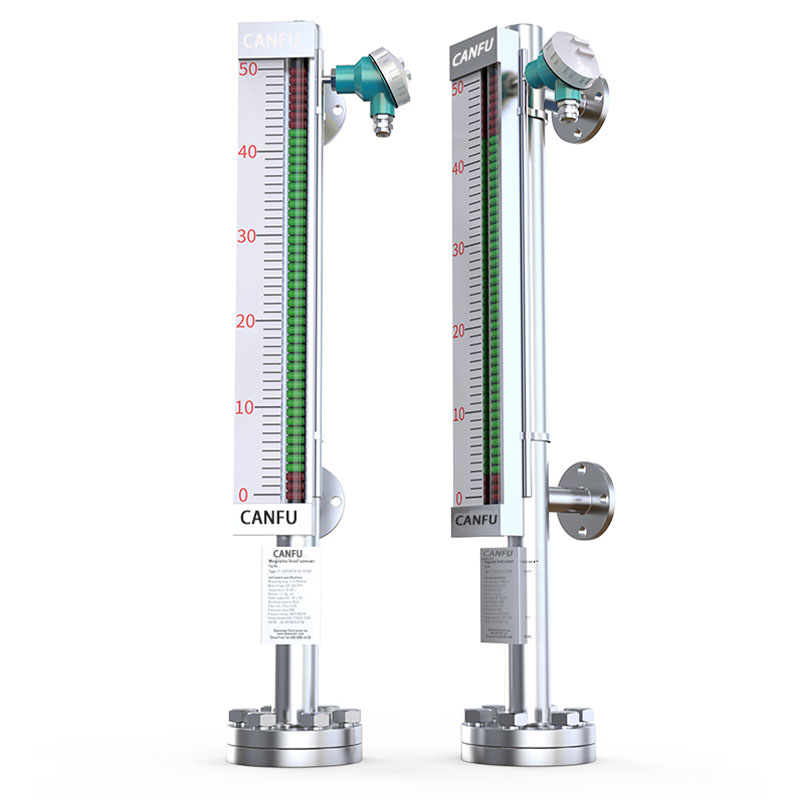

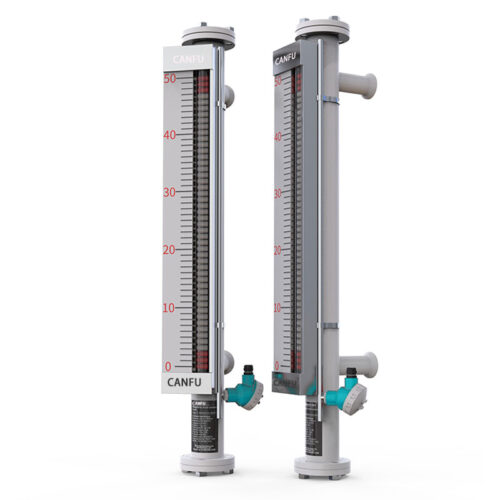

High-Temperature & High-Pressure Magnetic Level Gauge

Page Features:

・ Explosion-proof option available

・ No external power supply required

・ Resistant to high temperature and high pressure

・ Compatible with level switch sensors

・ Multiple installation and connection methods

Product Overview:

The High-Temperature & High-Pressure Magnetic Level Gauge (also known as Magnetic Float Level Gauge) operates based on buoyancy principles and magnetic coupling. As the liquid level in the container rises or falls, the magnetic float within the gauge’s main tube moves accordingly. The magnet inside the float transmits magnetic force to the magnetic flip indicator, causing red/white flip segments to rotate 180°. When the liquid level rises, segments turn from white to red; when it falls, segments turn from red to white. The interface between red and white indicates the actual liquid level height, ensuring clear visual indication.

Key Features:

■ Plastic-cased magnetic switch – Acid/alkali-resistant, IP67 protection, compact size for flexible positioning.

■ Novel bottom flange design – Prevents liquid residue; ideal for industries requiring frequent process changes. Enables complete drainage without cross-contamination.

■ Bottom-mountable – Fits tanks without bases, eliminating the need to elevate equipment (unlike traditional gauges).

■ Shock-absorbing springs – Added at top/bottom to protect floats during transport/installation.

■ Precision float welding – Laser-welded for reliability.

■ High temp/pressure resistance.

■ Modular indicators – Colors: red, green, white (customizable). Ceramic segments available for high-temp use without fading. Fluorescent options enhance visibility.

Technical Parameters

| Parameter | Specification |

|---|---|

| Compatible Media | Impurity-free liquids compatible with wetted materials |

| Density Range | 0.65–2.0 g/cm³ |

| Measuring Range | 300–6000 mm |

| Accuracy | ±10 mm |

| Resolution | ±1 mm |

| Repeatability | ≤±0.2% FS/year |

| Operating Temperature | -20–120°C (Standard) / -20–450°C (High-Temp) |

| Operating Pressure | 0.5–2.5 MPa, 1.0–5.0 MPa, 2.5–6.0 MPa (>300°C), 2.5–10 MPa (<300°C) |

| Output | Switch output (1–4 relay contacts optional); 4–20mA + HART protocol |

| Overload Pressure | 150% FS |

| Burst Pressure | 200% FS |

| Ambient Temperature | -40–80°C |

| Wetted Materials | SS304, 316L, Ti, PP, PVDF, PTFE, PPR |

| Flip Indicator | Frame: SUS304 Segments: Engineering plastic / Ceramic Colors: Red/White, Green/White Cover: Engineering plastic / Glass |

| Protection Rating | IP65 (IP68 optional) |

| Electrical Connection | Hose-man connector, junction box |

| Electrical Protection | Overload/reverse polarity protection |

| Installation | Side-side, Bottom-Top, Bottom-Side, Side-Top, Top-Mount |

| Connection | Sanitary clamp, Flanged, Threaded, Welded pipe |

| Accessories | Drain valve, Insulation jacket, Dust plug |

| Weight | Varies by measuring range |

Reviews

There are no reviews yet.