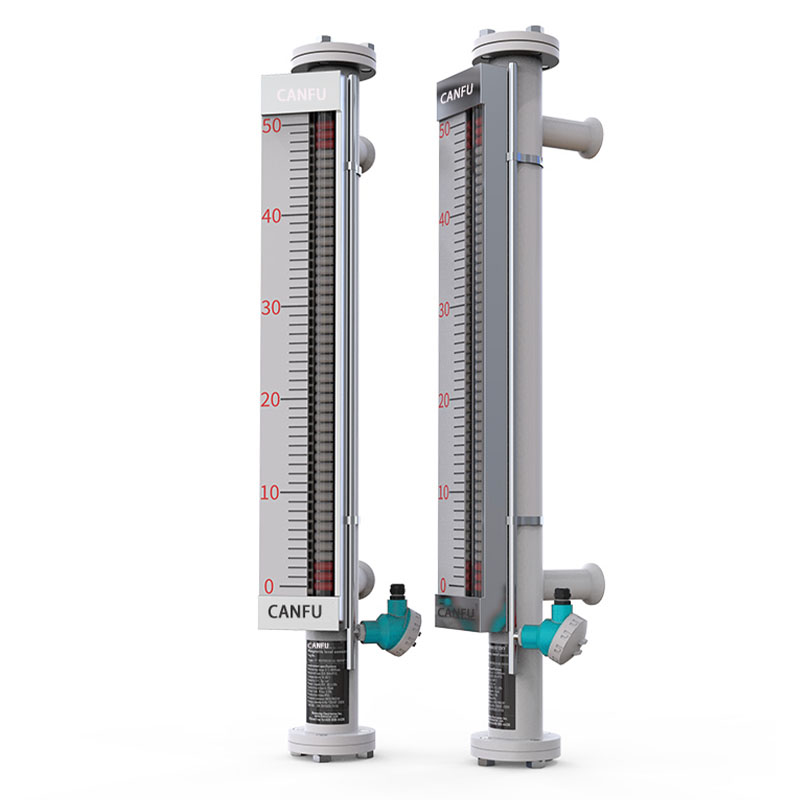

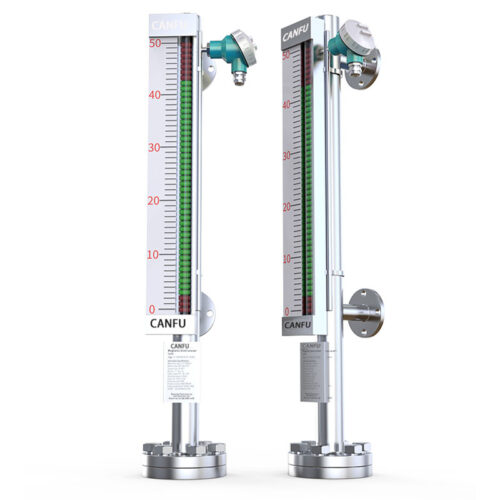

Anti-Corrosion Magnetic Flap Level Gauge

Page Features Description

No external power source required.

Blind-zone-free measurement throughout the entire range. Clear display, large measuring range.

Installation or adjustment can be performed at any time without shutdown.

Suitable for strong acids, strong alkalis, and highly corrosive environments.

Product Overview

The Magnetic Flap Level Gauge can be used for liquid level detection in various towers, tanks, vessels, spherical containers, boilers, and other equipment. The internal liquid level is clearly indicated by the magnetic flap indicator. Using high-quality lining and special float ball materials, it achieves high sealing, prevents leakage, and is suitable for strong acid, strong alkali, and highly toxic environments.

Performance Features

Level transmitter and magnetic switches can be added. Installation or adjustment can be performed at any time without shutdown.

Plastic housing magnetic switches resist acids and alkalis, with protection rating IP67.

Suitable for high temperature, high pressure, strong acids, and strong alkalis. Simple and robust structure, reliable and durable. Can be equipped with various optional accessories for easier control.

Can be installed at the bottom of equipment (tanks without bases), eliminating the need to elevate the equipment like traditional indicators.

Upper and lower ends feature spring buffer design to prevent float ball damage during installation and transportation.

Float ball magnetic field – 360-degree sensing. Dual magnets mutually excite, extending the magnetic field lines.

Color flaps (different colors every 10cm) for easy liquid level identification.

Unique punching technology minimizes burrs. Float ball is wear-resistant. Special workmanship ensures minimal leakage.

Magnetic switch position is adjustable for user convenience.

Technical Parameters

| Parameter | Specification |

|---|---|

| Suitable Media | Water, strong acids, strong alkalis, corrosive, toxic, and other impurity-free liquids |

| Suitable Density | 0.65 – 2.0 g/cm³ |

| Measuring Range | 300 – 6000 mm |

| Accuracy | ±10 mm |

| Resolution | ±1 mm |

| Repeatability | ≤ ±0.2% FS / Year |

| Operating Temperature | -20 to 120°C (Standard) -20 to 450°C (High-Temperature Type) |

| Operating Pressure | 0.5 – 2.5 MPa, 1.0 – 5.0 MPa, 2.5 – 6.0 MPa (>300°C), 2.5 – 10.0 MPa (<300°C) |

| Output | Switch Output: Relay output, 1-4 switch points optional Analog Output: 4-20mA + HART protocol |

| Overload Pressure | 150% FS |

| Burst Pressure | 200% FS |

| Ambient Temperature | -40 to 80°C |

| Wetted Parts Material | Stainless Steel 304, 316L, Ti, PP, PVDF, PTFE, PPR |

| Flap Indicator | Frame Material: SUS304 Flap Material: Engineering Plastic, Ceramic Flap Colors: Red/White, Green/White Cover Material: Engineering Plastic, Glass |

| Protection Rating | IP65 (IP68 optional) |

| Electrical Connection | Hose-man Connector, Junction Box |

| Electrical Protection | Overload / Reverse Polarity Protection |

| Installation Method | Side-Side, Bottom Inlet Top Outlet (BITO), Bottom Inlet Side Outlet (BISO), Side Inlet Top Outlet (SITO), Top Mount |

| Connection Method | Sanitary Clamp, Flange Connection, Threaded Installation, Welded Pipe Connection |

| Accessories | Drain Valve, Insulation/Heat Tracing Jacket, Dust Plug |

| Weight | Depends on measuring range |

Reviews

There are no reviews yet.